|

|

|

|

Except for deployment and recovery, the CTD

chain system is not labour intensive during operation. Watch keeping underway

can be put on any diligent person, if at least one specialist on measurements

in the ocean is at hand, who is familiar with the hard- and software of the

system. Duties of the watch-keeper are

The acquisition program

offers many display options. They can quite safely be changed by key commands

without influencing data acquisition. Dangerous key commands that would abandon

data storage require extra acknowledgement.

Two

ASCII files, which are required for data acquisition, should be prepared well

in advance of a deployment. The calibration file (a_name.CAL) contains

one line for each sensor fin. The sequence of lines is arbitrary. Each line

starts with the sensor address and a sensor type number followed by three times

three polynomial coefficients for the conversion of voltage readings of the

three measurement parameters into physical units. The configuration file (a_name.CFG)

has one line for each sensor fin in the sequence from the deepest to the

shallowest. The first column contains the sensor address, the second the

distance in tenths of metres from the tail of the chain, and the third a number

between 1 and 15 specifying one of 16 colours. The calibration and

configuration files are constituents of CTD chain data, since a binary chain

data file only holds voltage readings in the sequence specified by the

configuration. If it

is desired to test a CTD chain on shore, a few things must be preconceived.

Several hundred metres of insulated wire on a drum constitute a respectable

inductivity, against which the deck unit will likely not be able to operate.

There are two workarounds. The sensors may be stringed on a short laboratory

cable prior to configuration of the long chain. Or the long cable may be taken

from the drum and stretched out on the ground. A successful test does

however not guarantee flawless operation after deployment into the ocean. Due to energy loss into the surrounding water, a sensor fin in several hundred metres depth receives less energy from the deck unit and the amplitude of its answer is lower than that of a sensor fin positioned close to the

surface. Who wants to be sure that his deck unit

works with a several hundred metres long CTD chain, should once have tested the

system under real conditions at sea prior to a research cruise.

Sensor fins may optionally include a fourth parameter such as oxygen.

In order not to extend the sensor message by two more bytes, only three of

four parameters should be selected simultaneously, though. A CTD chain sensor configuration program

named CTDsc.exe is at the users disposal, by means of which the operation mode and operational parameters of

underwater units can be changed. CTDsc.exe replaces the older DOS program CTDSENS.EXE.

When the sensor configuration program is run, the same precautions must be taken as described below for the

acqusition program in order to avoid excessive supply current from the deck unit. Cruise

preparation includes the configuration of the wet part of the system. Although

the chain can well be reconfigured during the cruise, it is mostly preferred to

specify chain length and sensor fin separations for a complete cruise. Sensor

fins are fixed at their positions with stoppers, the spaces filled with

fairings, and the cable terminated with a thimble in advance. If the chain

shall be placed below a towed float, a water tight upper termination is

prepared, which includes an underwater connector for attachment to a single

conductor armed towing cable.

During

deployment the ship should be stopped or proceed extremely slowly ( < 2

knots). The depressor is deployed first. A swivel is inserted between the

depressor and the thimble at the lower end of the chain. Fairings are mounted

filling all space between sensor fins. The fairings are not only essential for

drag reduction, they also eliminate the risk of the cable insulation to be

damaged during deployment, especially if a chute is used instead of a pulley.

It is recommended to plug the upper end of the tow cable to the

slip ring of the winch, from where the connection with the deck unit via a single

conductor cable can be prepared well in advance. If the winch is not equipped with

a slip ring, the connection is established after the winch drum was rotated into

its final position. The deck unit or at least the power of the supply current source

of the CTD chain should remain off until data acquisition starts.

Technical details of operation in a DOS based system were described in the paragraph “Chain control and data acquisition” in the system

description. Prior to program launching under DOS, date and time should be accurately set

to the same time zone that is used in the (external) GPS navigation log,

preferably UTC. CTD chain records will

be triggered by the real-time clock of the acquisition PC. Date and time read

from the RTC are constituents of each data record. In a more modern configuration based on a Windows PC and USB link between PC and deck unit,

time stamps of the records are coming from an internal real-time clock inside the USB link.

The host computer initializes that real-time clock with system time (UTC) as soon as the “start deck unit”

button is clicked in the acquisition program. Subsequent time adjustments of the host computer, e.g.

by a time server, do not affect regular record timing of the CTD chain system. When the “start deck unit” command is isued, the USB link periodically switches the RTS signal

of the deck unit as described in Bus signals

and polls the sensors in the predefined sequence.

Not earlier than now the chain supply voltage should be switched on and

slowly increased to the level where

the sensor fins are sufficiently powered and their answers appear on the

graphic and

alphanumeric displays. The operator must bear in mind that after having

reached the appropriate supply voltage the overall impedance of the CTD

chain decreases with increasing supply voltage, i.e. the current can

suddenly increase. An excessive supply current of several Amperes may be

destructive. When the system runs correctly with all sensors working, writing into a

data file is started with an extra key command or button.

CTD chain data files always reside in the same directory with the

associated configuration and calibration files.

It is advised to store all data of a deployment phase into one single

contiguous file.

It is easier to postprocess and cut data files according to ship tracks

than to acquire short files that are postprocessed separately.

During acquisition, the graphical real-time display shows the most

recent data, one record per pixel column. The image is horizontally

scrolled as the measurements progress. Changing display parameters of the program does not interfere with data acquisition, which is interrupt

driven with higher priority. Additional tasks running on the acquisition PC do probably not disturb chain data acquisition,

except particularly demanding system tasks such as software updates. It is therefore advised not to allow the PC to be updated

during data acquisition. In case of missing service of the USB interface for more than 0.3 seconds, synchronization between

USB link and PC is lost and no more data acquired, although the link is still working and controlling the deck unit.

In that case the file should be closed, the USB connector unplugged for a few seconds, and the acquisition procedure

started from the beginning.

Often

it is preferred to store final data as calibrated and filtered physical values

and forget about raw data. This is e.g. agreeable for standard CTD casts which

are usually stored at fixed vertical intervals in contrast to raw time series.

For CTD chain data it is suggested to keep raw uncalibrated data and apply

calibration polynomials and seawater equations whenever chain data are

displayed or used for something else. Postprocessing

in this sense is restricted on the removal of occasional outliers which appear

due to byte transmission errors from the CTD chain to the deck unit, and on

fine tuning of polynomial coefficients. Fine tuning beyond nominal sensor

accuracy helps to remove bothering sensor trails in two-dimensional false

colour images of sea water properties. Experienced

Matlab users are invited to

use the functions of a CTD chain toolbox for data postprocessing and presentation.

|

Running

CTDCHAIN.EXE for a single sensor fin in the laboratory.

Running

CTDCHAIN.EXE for a single sensor fin in the laboratory.

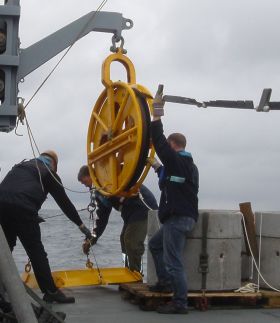

Crew

involved in chain deployment must be aware that sensor fins, though moulded

with robust and abrasion insensitive potting compound, are delicate

oceanographic instruments. Care must be taken that no fin interlocks at an

obstacle during deployment or recovery. Fins must be held in an upright

position when they pass the pulley or chute. The fin edge, which contains the

ferrite ring core of the inductive coupler, is protected by stoppers on both

sides, whose diameter is larger than the fin thickness. The usage of too small

pulleys on the chain’s path from the winch into the water would contradict the

protection by stoppers.

Crew

involved in chain deployment must be aware that sensor fins, though moulded

with robust and abrasion insensitive potting compound, are delicate

oceanographic instruments. Care must be taken that no fin interlocks at an

obstacle during deployment or recovery. Fins must be held in an upright

position when they pass the pulley or chute. The fin edge, which contains the

ferrite ring core of the inductive coupler, is protected by stoppers on both

sides, whose diameter is larger than the fin thickness. The usage of too small

pulleys on the chain’s path from the winch into the water would contradict the

protection by stoppers.